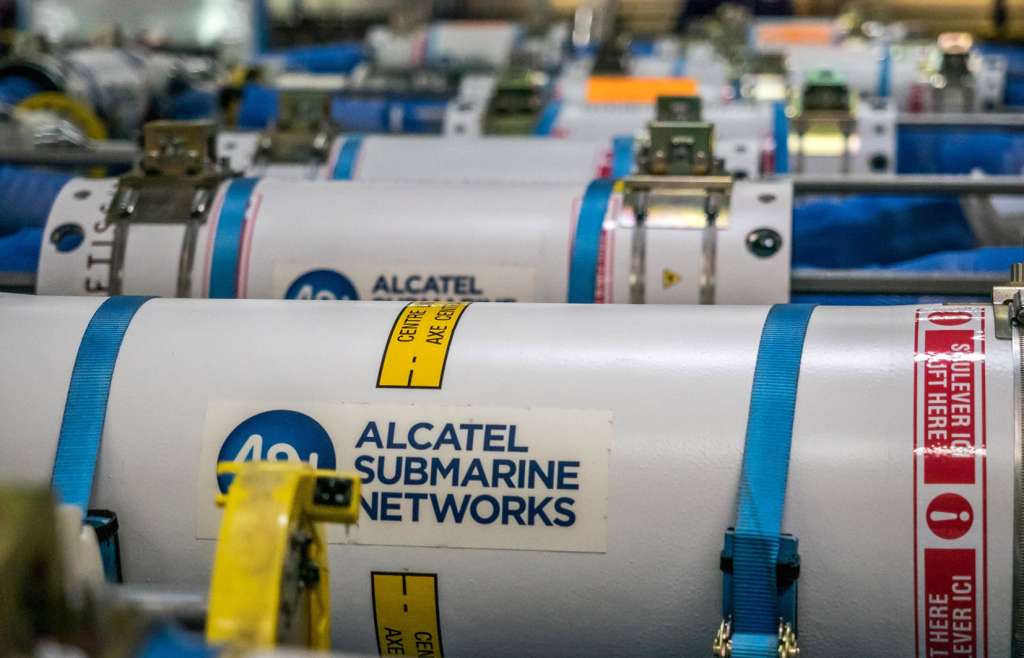

The world leader in the manufacture and installation of submarine cables has implemented a new digital strategy to help it meet rising global demand for its services.

Alcatel Submarine Networks (ASN), which has a manufacturing plant in Greenwich in London, has turned to digital transformation specialist PTC to digitise its product documentation and create a single digital thread for use across its PLM, ERP and MOM (Manufacturing Operations Management) systems.

It begins with design data from Creo CAD software, then Windchill PLM software centralises and manages all the product data, before ThingWorx Industrial IoT solution serves as an integration platform between the data from Windchill and the manufacturing data from the ERP.

“We have embarked on an in-depth transformation in order to improve efficiency and respond to changes in a fast-growing market,” commented Paul Tandy, Business Solution Lead at ASN in the UK.

“The implementation of an ambitious Industrial 4.0 programme – based on 5G and digital continuity – supports our quest for innovation and performance in the service of our customers and meeting a sharp rise in orders – linked to the increasing need for reliable network transmission, cloud services and deep-water oil and gas exploration.”

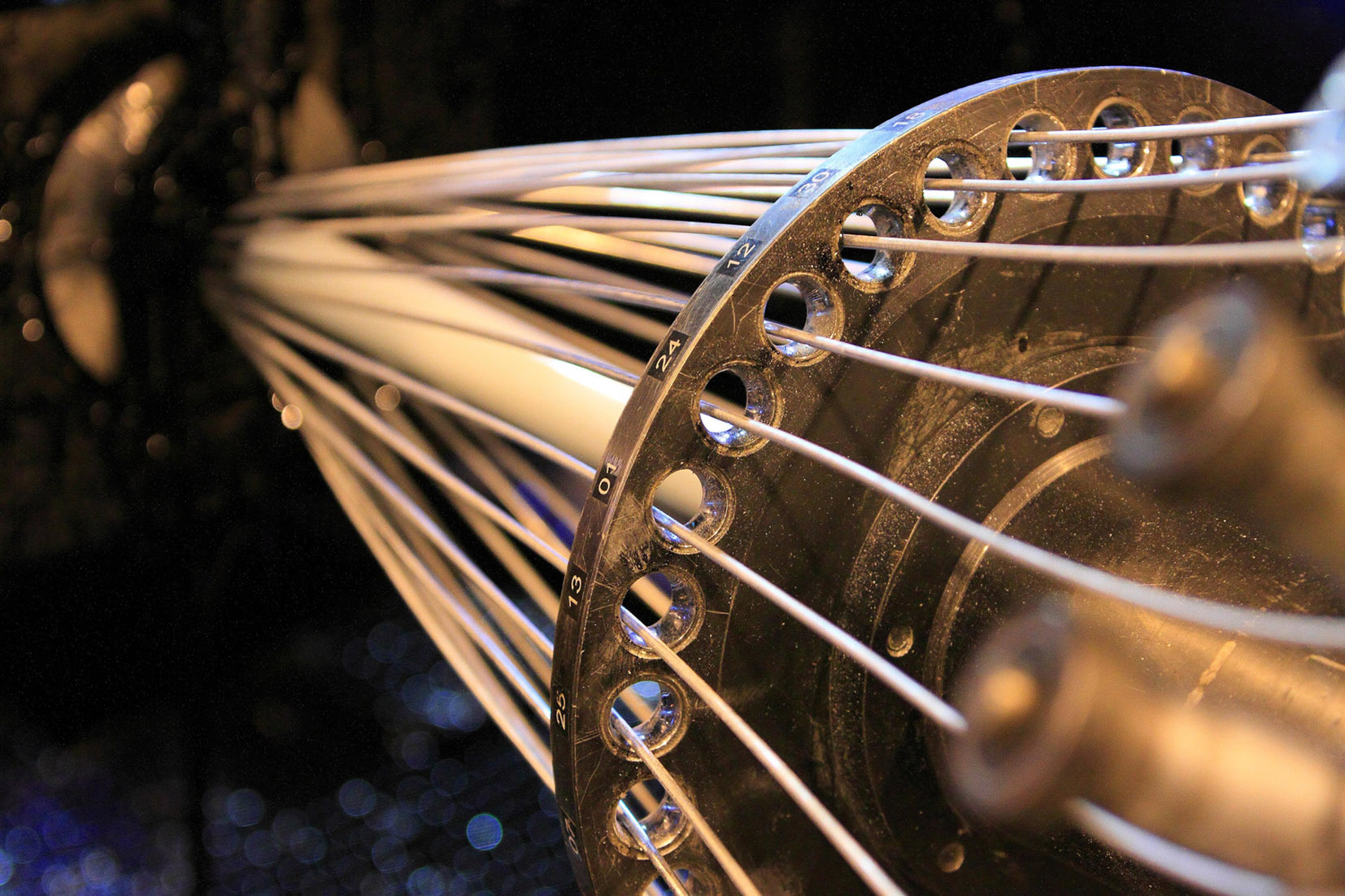

The implementation of the project began with one product in particular: the PRM, a new system for the permanent monitoring of oil slicks (reservoirs) and the result of collaborative manufacturing between ASN’s R&D site in Trondheim, and its plants in Greenwich and Calais.

Initial design stages are carried out by Norwegian teams, the design data is then loaded into Windchill for real-time sharing with the UK factory where the PRM is assembled, and then in France where the system is finalised.

Previously, production data was only available in paper format and did not leave the factory, but with the technical support and solutions of PTC, the complete product information chain is available to teams at both factories at any time, within a single ecosystem.

More specifically, this data relates to product characteristics, the manufacturing machines used, the date of manufacture and all the information needed for traceability. For its part, the ERP provides information on the raw materials and sub-assemblies used and their suppliers.

This continuous digital chain offers extensive benefits across all ASN’s sites and enables data from PLM and ERP to be used to generate manufacturing ranges and instructions.

Elliot Clarke, UKi Regional Director at PTC, added his support: “Alcatel Submarine Networks has more than 750,000km of optical submarine systems deployed worldwide – that’s enough to circle the globe 19 times.

“This figure is only going to grow, and the company had to find an effective way of digitising very complex operations, a challenge we were only too happy to assist with. The pleasing thing here is how the management team wanted a single digital thread and appreciated it wasn’t going to be a quick and instant solution.”

He concluded: “We are now in a position where the digital transformation will be embedded across the entire company ecosystem, with the operational benefits already starting to flow.”

For further information, please visit www.ptc.com or follow @ptc on twitter